Bead for use in a milling device

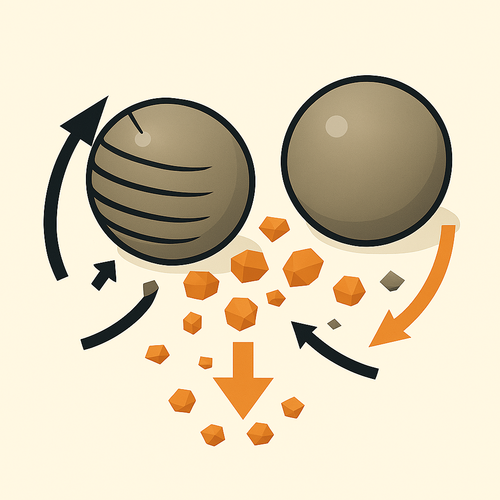

A spherical bead with engineered grooves and/or protrusions boosts mass transfer and kinetic energy in mechanochemical milling. Its modified surface prevents caking and enhances reaction efficiency.

Innovation Explanation

The invention describes a milling bead retaining a spherical form but featuring recesses and protrusions that increase surface area by up to 10 % of its diameter. These surface structures can be rings—single or in intersecting planes—or patterns of grooves and bulges. Made from materials like stainless steel, ceramic, zirconia, or tungsten carbide, the beads fit into rotating planetary or other ball mills. Their textured surface traps and shears particles, improving homogenization, preventing clumping, and elevating kinetic energy input. Demonstrations include rapid co-crystallization of nicotinamide/salicylic acid, efficient phosphorus allotrope conversion, and accelerated TiO₂ size reduction—all outperforming smooth beads under identical conditions.

Key Innovation Features and Advantages

- Modified spherical surface (grooves/protrusions) increases bead–particle contact and mixing.

- Ring patterns in one or two perpendicular planes boost shear and friction.

- Broad material compatibility (metals, ceramics, polymers) for diverse milling chemistries.

- Enhanced kinetic energy output yields faster reaction turnover and finer particle sizes.

Use Cases

- Solid-state co-crystallization of pharmaceutical actives.

- Mechanochemical conversion of elemental allotropes (e.g., red to black phosphorus).

- Rapid particle size reduction for pigments, catalysts, or battery materials.

Commercial Opportunities

- Licensing to ball-mill equipment manufacturers as upgraded milling media.

- Supply of specialty beads to pharmaceutical and advanced-materials industries.

- Integration into solvent-free, sustainable mechanochemical processes for green chemistry.

Current Status

Published as EP 4 563 227 A1 on 04.06.2025, assigned to Freie Universität Berlin. Inventors: Rainer Haag and Obida Bawadkji. No granted‐status update yet.

Keywords

- milling bead, mechanochemistry, mass transfer, surface structure, co-crystallization, particle size reduction, allotrope conversion